Fixture of drilling machine is shorted for drilling machine die that is used to process holes and threads. The Fixture is mainly composed of drill bush, location device and clamping device, etc. Due to feeds less movement and the structural features, drilling machining tends to be lower precision, led to uncomfortably guarantee the accuracy of multi-holes drilling, so that, fixture of drilling machine plays a decisive role in drilling accuracy, and also fixture of drilling machine is the most widely used in all fixtures.

Structure of Drilling Jig

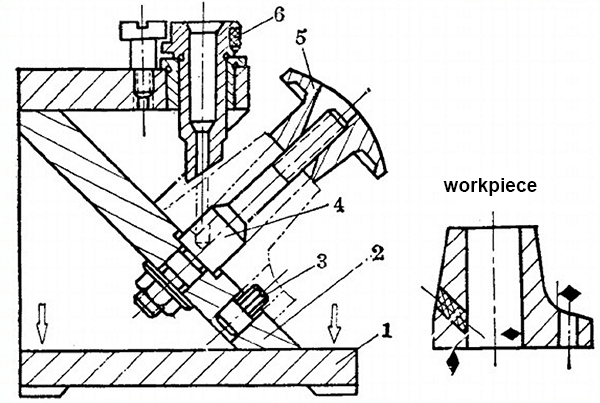

1. Fixed Drilling Jig

The type of drilling jig is fixed in the position of the drilling machine, and it has higher processing accuracy, mainly used for drilling single hole with larger diameter in vertical drilling machine, and parallel hole-series in radial drilling machine.

Fixed Drilling Jig

2. Turnover Drill Jig

Turnover Drill Jig is used for drilling hole of small workpiece in different surfaces, the diameter is about φ8-φ10. It will reduce the assembly times; improve the position accuracy of the processed holes.

Turnover Drill Jig

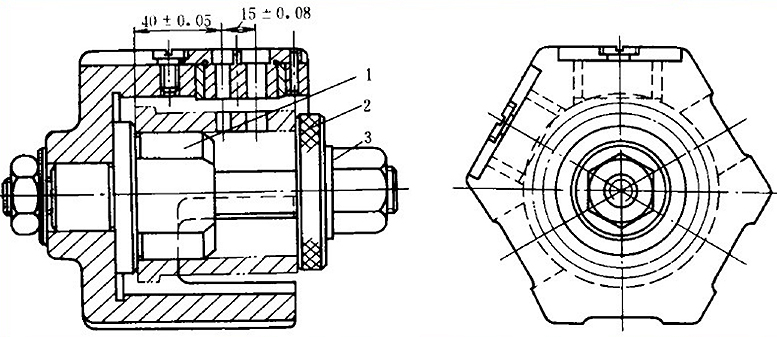

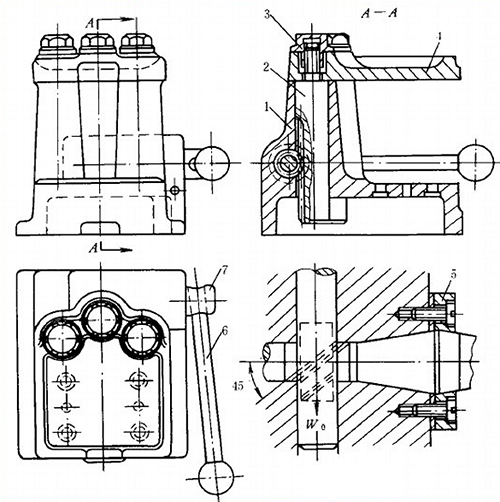

3. Rotary Drill Jig

The type of drill jig has an indexing mechanism, so that it will drill some hoe series that are distributed around the axis in axial direction or radial direction.

Rotary Drill Jig

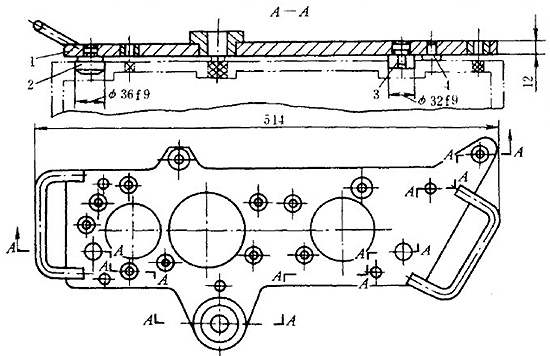

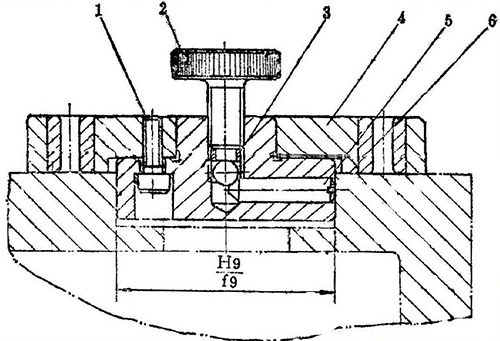

4. Flat Top Drill Jig

There is no fixture in flat top drill jig, its location device and clamping device are directly assembled on the drilling template, and then drilling template is clamped on workpiece, it suitable for drilling small holes in bulky and bulky workpieces, due to simple and light structure of jig, easily clear the filings.

Flat Top Drill Jig

Flat Top Drill Jig

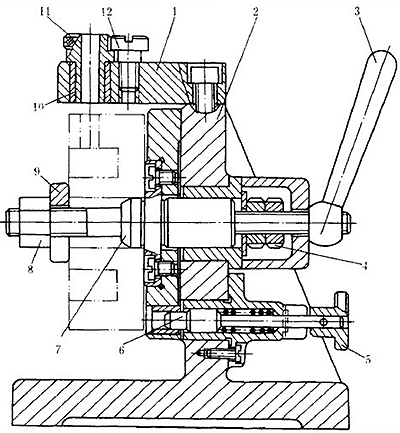

5. Strut Bar Drill Jig

Strut Bar Drill Jig is an adjustable fixture with rise and fall drilling template, this kind of drill jig has the advantages of simple structure and easy operation and short manufacturing cycle, which is widely used in production.

The Latching Principle of Strut Bar Drill Jig

If you want to know more about drill jig, please read our another article: Features of Drill Jig article link: http://www.drillbitgrinder.com/features-of-drill-jig/