The drill bit is the best cutting tool for grinding.

The design should consider the need for grinding.

For preprocessing or general hole accuracy, degree of the drill bit grinding is worn at most 20 times. For high precision drilling bit, it can be sharpened 5 times.

Tag Archives: drill bit

Solutions Summary of Common Drilling Problems (Relationship with the Good or Bad Grinding Drill Bit)

In the actual production, PURROS Machinery has collected mass customers’ problems about grinding drill bits by hand (manual grinding drill bits), now, list the summary of the problems and how to solve as bellow for your reference and study. In the actual production, PURROS Machinery has collected mass customers’ problems about grinding drill bits by hand (manual grinding drill bits), now, list the summary of the problems and how to solve as bellow for your reference and study.

Do you know how many different kinds of drill bits? (Classification by Use)

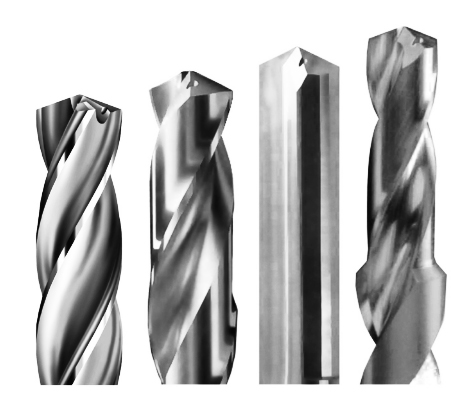

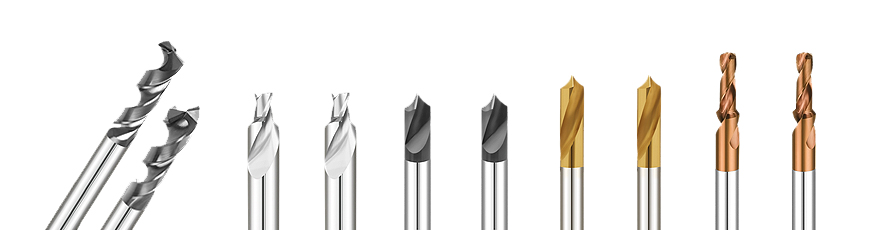

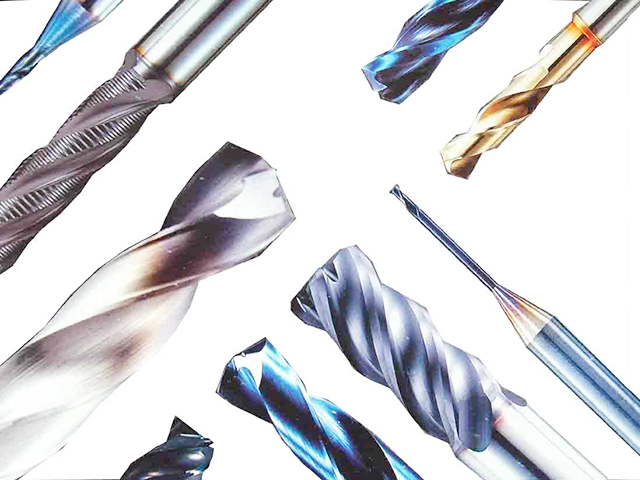

Classification of Drill Bits

Drill bits come in a wide range of shapes and sizes, and are available in a variety of materials and coatings. Most tooling and machining operations have a drill bit that’s designed specifically for the task. Here’s a quick overview of several types of drill bits, materials and design types.

Do you know how many different kinds of drill bits? (Classification by Construction and Shank types)

Drill bits are the special rotating tools that have cutting capacity at the top. Generally, drill bits are made from carbon steel (SK), HHS (SKH2, SKH3), etc, and then by milling machining or quenching after rolling, the final step is the grinding after tempering heat treatment. Drill bits are used for machining metals or other materials. Drill bits have a wide useful, such as drilling machine, lathe machine, milling machine and power drill, etc.

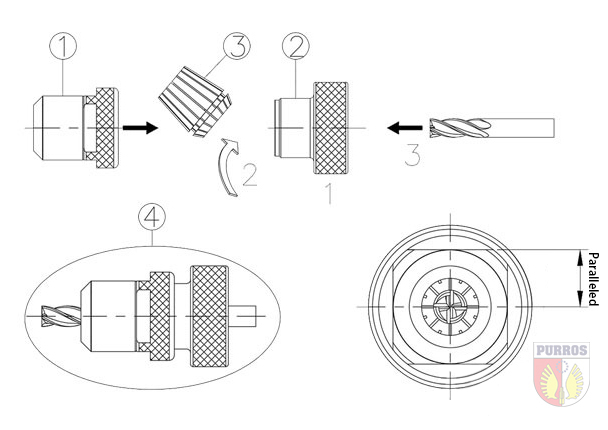

Operations Guide of Drill Bit Grinding

First: Preparation Before Grinding

A: Assembly of Drill Bit and Fixture

- Checking the diameter of drill bit shank, then select the suitable collet chuck and cutting sets.

- Insert the collet chuck into the fixture and lock the nut.

- Put the drill bit into the collet chuck, and keep 35~50mm out of the collet chuck.

- Adjust the scale to suit the outer diameter of the drill bit, and adjust the angle of point angle.

Attention: Keep some margin for adjusting before locking the chuck sets.

What is the difference between carpenter drill bits and metal drill bits?

Carpenter Drill Bit: The carpenter drill bit for drilling wood there has larger amount of stock removal. Generally, it is made of ordinary carbon steel, the manufacturing process of the carpenter drill is simple, such as forging, stamping, grinding, etc.

Metal Drill Bit: Generally, the metal drill bit is made of alloy of hardness or HHS(high-speed steel), etc. The metal drill bit is cast and molded, after that to be grinded by grinding wheel on the grinding machine. Its manufacturing process is more complicated than carpenter drill bit.

How many kinds of drills according to different materials?

The drill bits are special cutters that are used to drill through holes or blind holes in solid materials, and also reaming holes in existing holes. The most commonly used drills are twist drill, flat drill, centre drill, deep-hole drill and trepanning drill. Although reaming drill and M drill can’t be drilled holes in solid material, but they are also customary to put them in the drill bit classes.

Classification of drill bits are: HHS drill bits, carbide drill bits, tungsten drill bits.

How to throw off frustrated drill bit sharpening work?

How to throw off frustrated drill bit sharpening work?

Traditional Grinding Drill Bit by Hand

How does the twist drill bit sharpen can be more sharper?

The twist drill bit is the most commonly used cutting tool, the twist drill bit wants to be sharpened, so pay attention to some points below to:

For mechanical processing, twist drill bit is the most important of drilling tool, in all itsstructure simplicity,but it’s not easy to sharpen it right. The keypoint is to master the sharpening methodsand skills.If the method is mastered, the problem will be solved.Let me introduce the manual grinding of twist drill bit.

Usually, the point angle of twist drill bit is about 118°,it could also be treated 120°, the sharpening skills as follows:Continue reading

How to extend drill bit service life?

The drill has been widely used, but the cost of materials is high and reasonable use of drill bit can save cost. So how to extend the service life of the drill bit? Please read the following maintenance methods carefully.

Bit maintenance and drilling attention

How to extend drill bit service life? Sharpen drill bit on grinder attention.