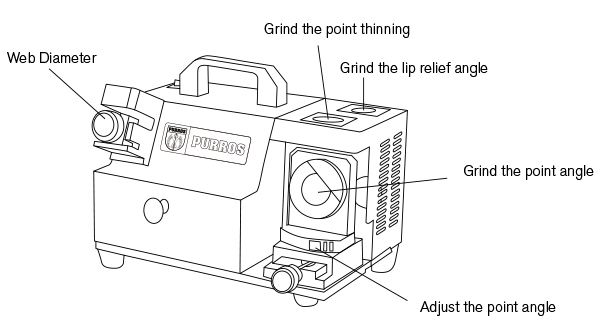

How to grind the drill to be sharp and durable?

- Sharpen the chisel edge to be a little bit shorter, but it can’t be removed, reducing the feed resistance.

- Take advantage of the opportunity to shorten the chisel edge and try to improve the negative land angle at the chisel edge. Increase the land angle of this place can reduce the cutting force, make drilling light.

- Use the larger Lip Relief Angle. Reduce friction resistance and make drilling easy.

- Reduce the point angle. The proper reduction of point angle can increase the positive pressure of the cutting edge on the cutting surface, which is the same with the v-belt drive. But too small will affect the front angle of the cutting edge.

- The holes with less strict aperture and roughness can keep the slight imbalance between the two edges. In this way, the hole diameter at the orifice is slightly larger, which can reduce the friction between the blade belt and the orifice wall.

If you choose a drill bit grinder to repair and grind your bit, it will save you a lot of trouble. Fool operation, simple, a few minutes to complete the bit grinding work.