- abrasive grain

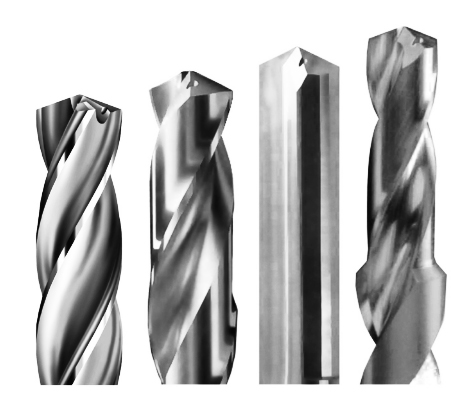

The grinding wheel of different materials is suitable for grinding different kinds of cutting tools. Different parts of the tool need to be used in different sizes to ensure the best combination of blade protection and processing efficiency.

Alumina: used for grinding HSS drill bit. The grinding wheel is cheap and easy to be modified into different shapes for grinding complicated knives.

Silicon carbide: used to modify the CBN wheel and diamond wheel.

CBN (cubic boron carbide) : used for grinding HSS drill bit.

Diamond: used for grinding HM drill bit.

PURROS drill bit grinder with best grinding wheel.

Drill’s Grinding Wheel, 4.5 grinding wheel, 3 grinding wheel, 4 grinding wheel, 6 grinding wheel, 7 grinding wheel, 8 grinding wheel

- Shape of grinding wheel

In order to facilitate the grinding of different parts of the tool, the grinding wheel should have different shapes. The most common ones are:

Parallel grinding wheel (1A1): grinding top Angle, outer diameter, back, etc.

Disc wheel (12V9,11V9): grinding spiral groove, the main of milling cutter, cutting edge, trimming blade, etc.

After a period of use, the grinding wheel needs to be modified (including plane, Angle and rounded Angle R). The grinding wheel must always be cleaned with the cleaning stone to clean up the chips to improve the grinding ability of the grinding wheel.