Description

Description

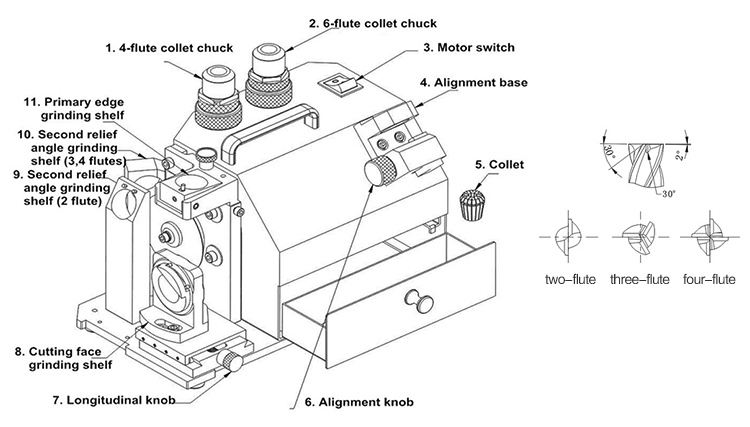

End mill grinder is a versatile grinding device that can be applied for cutting operations which need to be done in different angles. With this extensive types of cuts over different materials are carried out in accordance with the specific industrial usage.

| Model: | PG-X3A |

| Diameter: | Φ4-Φ20mm |

| Power: | 220V/160W |

| Speed: | 4400RPM |

| Point angle: | 0°-5° |

| Dimension: | 35*26*27CM |

| Weight: | 16KG |

| Standard Model: | Grinding wheel(4-14mm) :SDC (for carbide)×1 |

| Grinding wheel(16-20mm) :SDC (for carbide)×1 | |

| Types of ER20 collet: Φ4,Φ6,Φ8,Φ10,Φ12,Φ14 | |

| Types of ER40 collect: Φ16,Φ18,Φ20 | |

| Two collet chucks( 4-14mm):2, 4 flutes *1 piece; 3, 6 flutes*1 piece | |

| Two collet chucks( 16-20mm):2, 4 flutes *1 piece; 3, 6 flutes*1 piec | |

| Optional Model: | Grinding wheel(4-14mm): CBN (for HSS) |

| Grinding wheel(16-20mm): CBN (for HSS) |

Features:

It is a good alternative for conventional mills and above all it is cost effective and shows enhanced performance. It is without doubt one of the versatile tools designed for smooth and accurate milling process. This equipment helps to make different shapes of metal components and works several steps ahead than of conventional tool as in traditional process possibilities of this equipment to break were found to be higher as the edge of this instrument becomes comparatively weaker. This tool is highly supportive in this aspect as the operator can create intricate drilling and effective sharpness with least difficulties.

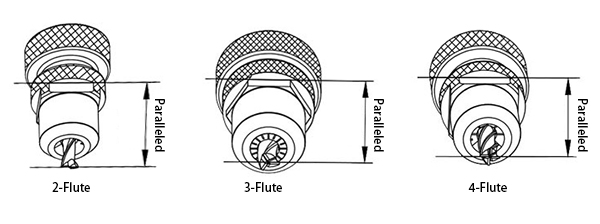

2-Flute End Mills

3-Flute End Mills

4-Flute End Mills

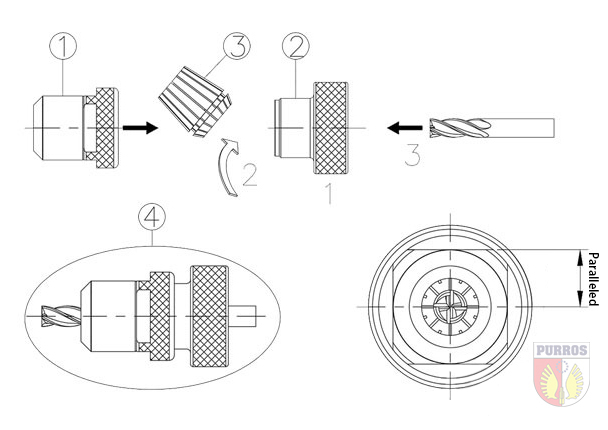

Fabricating of Milling Cutter

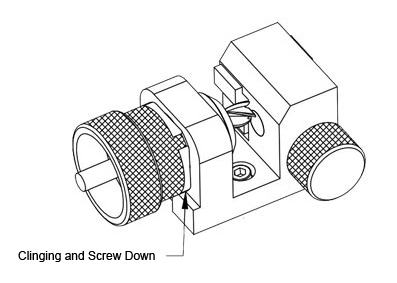

Calibration of Milling Cutter

Reviews

There are no reviews yet.