- Cause: Feed rate is too large

Solution: Decrease feed rate, because too large feeding that will increase the cutting resistance. - Cause: Point dimensions are not suitable

Solution: Select correct point dimensions, for example: the point angle is small, but the rigidity of cutting material is big. - Cause: Tool materials is not suitable

Solution: Choose a suitable tool material that means choosing a bigger rigidity of material for making cutter. - Cause: Relief angle is too small

Solution: Increase relief angle, because too small relief angle will Increase the wear and tear of flank face.

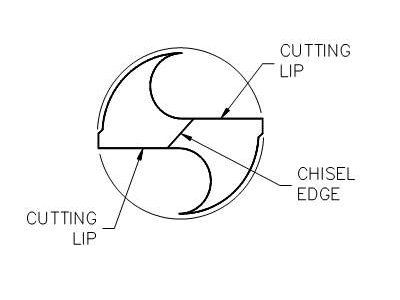

How to solve the large wear and chipping, crushing of the chisel edge?

Posted in Technology and tagged chisel edge, chisel edge chipping, chisel edge crushing, large wear of chisel edge, relief angle, solve large wear of chisel edge.