In actual work, we will encounter some special machining phenomenon, such as machining a larger diameter hole, or bottom of hole should beflat. Today, here we introduce reaming and countersinking, let’s go.

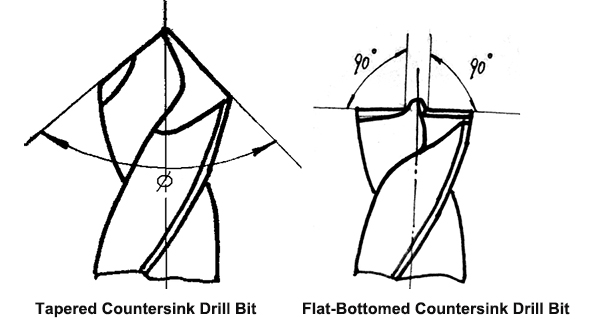

Countersink Holes usually involves countersinking flat-bottomed hole and countersinking tapered counter bore.

1. Reaming

In practice, it is impossible for drilling a larger diameter holes at once, so that we should drill a small hole atthe first step, after that then to ream the hole by large diameter drill bit.

During reaming hole by twist drill bit, before the diameter of hole should be kept in 0.5-0.7 times of after reaming. (A few years ago, i chose a larger diameter hole for reaming, when I was reaming there is a greater vibration is produced, it is very danger. One man’s fault is other man’s lesson.)

2. Refit the Countersink Drill Bit with a Twist Drill

Countersink Holes usually involves countersinking flat-bottomed hole and countersinking tapered counter bore. The RPM of the countersinking and reaming are the same.