The twist drill bit is the most commonly used cutting tool, the twist drill bit wants to be sharpened, so pay attention to some points below to:

For mechanical processing, twist drill bit is the most important of drilling tool, in all itsstructure simplicity,but it’s not easy to sharpen it right. The keypoint is to master the sharpening methodsand skills.If the method is mastered, the problem will be solved.Let me introduce the manual grinding of twist drill bit.

Usually, the point angle of twist drill bit is about 118°,it could also be treated 120°, the sharpening skills as follows:

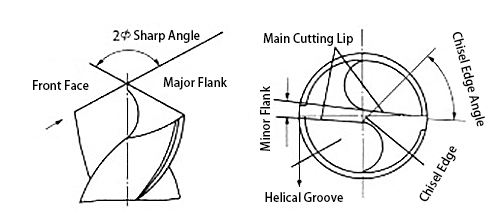

Sharpening Angle of Standard twist drill bit

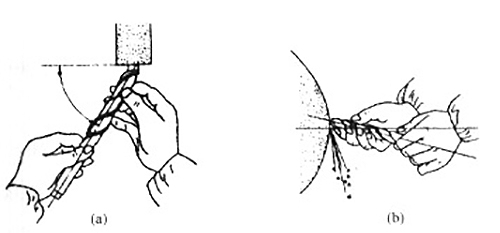

1. The cutter edge that is sharpened should be paralleledwith the grinding wheel.

Before sharpening, keeping the main cutting lip of twist drill bitwith the grinding wheel in the same horizontal, in other words, to keep all of the face of main cutting lip can be sharpened by grinding wheel. The correct position is the first step, and then goes head to grinding wheel slowly.

2. Theaxis of twist drill bitand thetilted surface of grinding wheel should be kept about 60° angle.

This is the sharp angle of twist drill bit that is about 60° angle, if not correct, it will directly affect the point angle of the twist drill bit, the shape of the main cutting lip and chisel edge angle. Pay attention to the horizontal position and the 60°angleof twist drill bit before sharpening, both should be balanced, it is not allow to ignore the angle in order tochisel edgebalancing, orthe opposite is not allow yet.

3. Sharpening from front to back

After the chisel edge touching the grinding wheel, the sharpening direction should be from the main cutting lip to back, it is that to touch the grinding wheel from cutting edge to back to sharpen slowly. First time sharpening, twist drill bit is touched the grinding wheel gently for a little of sharpening, and observing the uniformity of the spark, adjustingthe forcefrom your hand in time.Also cooling of twist drill bit is important, it should be observed continuously, do not allow it be overdone, caused the cutting edge is discolored and annealed.If the temperature is over, the drill must be cooled immediately.

Sharpening methodof Standard twist drill bit

4. The cutting edge of twist drill bit should be swung up and down, and the end of twist drill bit does not allowraised up.

It is the standard methodfor twist drill bit sharpening that main cutting lip can be swung up and down on the grinding wheel, it is that the front of twist shank can be swung up and down on the grinding wheel surface when operator shaking, but the end of twist does not allow shaking, at the same time, to preventthe end of twist drill bit does not allow raised up, the end of twist shank does not higher than horizontal center line of grinding wheel, otherwise it will be blunted, thus unable to cutting. The point is vital, please be carefully.If something bad happens, still do not worried, to touch the end of chisel edgewith grinding wheel lightly that the surface of chisel edge will become smooth.

5. Ensure the tip of the blade to the axis, both sides symmetrical slowly.

The drill can be sharpened at the edge of the cutting edge, and then the cutting edge of the drill must be finished. The cutting edge must be in the middle of the drill axis, and the edges of both sides should be symmetrical. The experienced master will examine the symmetry of the drill point and slowly grind it.

6. Both of chisel edge are finished, spear point of drill bit should be sharpened for larger diameter of twist drill bit.

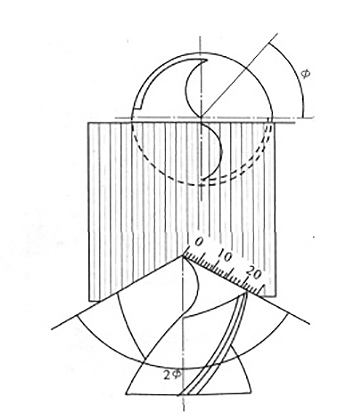

Inspection Anglewith Tool

Both of chisel edge are finished, both of the spear point of drill bit will forms a plane that will affect the center positioning of the twist drill bit, so it should be chamfered, to keep the plane smaller as soon as possible after chamfering. The operation method is that keeping the twist drill bit up on the corner of the grinding wheel, to chamfer a bit slot at the end of chisel edge. It is the important for locating center of twist drill bit and cutting easily. Pay attention to chamfering, there is not allow that main cutting lip be chamfered, that will cause the bigger front angle of main cutting lip, go on affecting the drilling.

Of course, the method of twist drill bit sharpening is notunique, it is necessary to accumulate experience in practical operation. By comparing and observing repeated tests, it will be better to sharpen the twist drill bit. Look after you!