Fine Sharpening Lathe Tool

- (1)Fine Sharpening Flute: In order to make the shape of flute more precision, and surface roughness is finer than before, so flute should be fine sharpened after rough sharpening. The sharpening method is the same as rough sharpening.

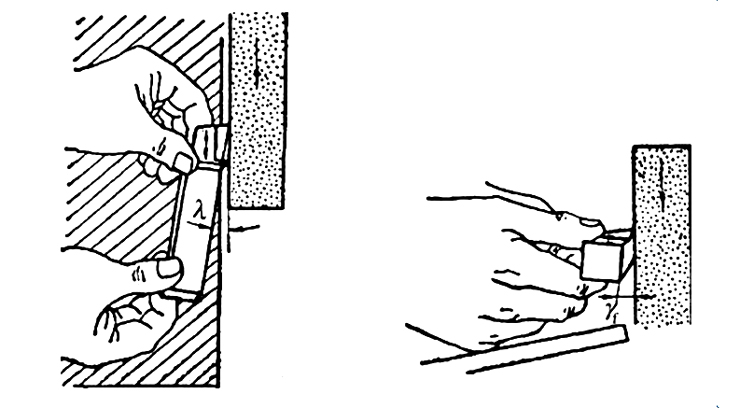

- (2)Sharpening Negative Chamfering: Negative Chamfering is commonly sharpened by end of grinding wheel, the granularity between 100# to 200#. The sharpening method as follow the figure :

(a) Sharpening position is that along the edge of the blade direction.

(b) Sharpening position is that along the edge of the blade vertical direction.

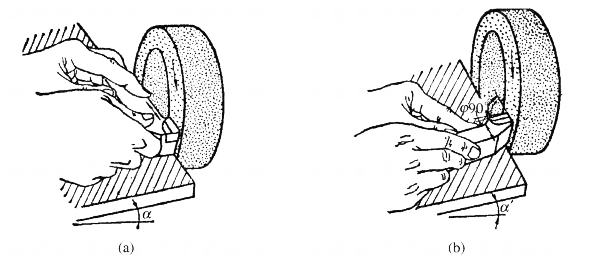

- (3)Fine Sharpening Major Flank Face and Minor Flank Face: The sharpening method as follow the figure, selected grinding wheel is the same as Negative Chamfering. It should be stopped when major cutting lip is finished and the negative chamfering width meets the requirements.

(a) Fine Sharpening Major Flank Face (b) Fine Sharpening Minor Flank Face

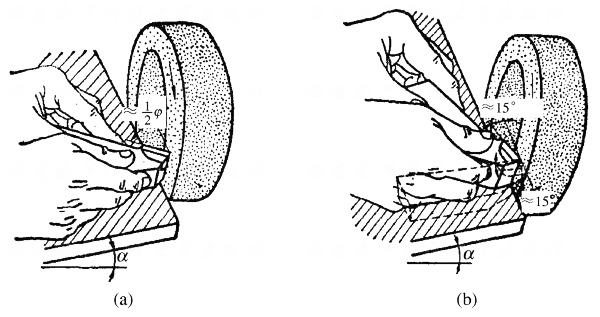

- (4)Sharpening Transition Blade: The method of sharpening transition edge as follow the figure:

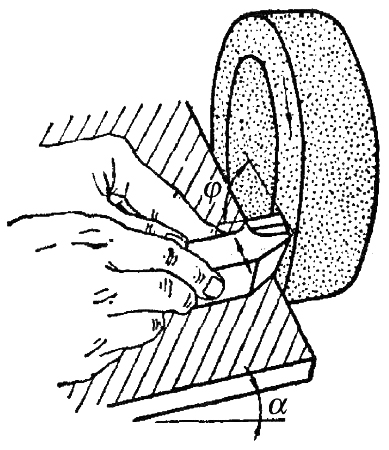

- (5)Sharpening Top Blade: The method of sharpening top blade as follow figure: