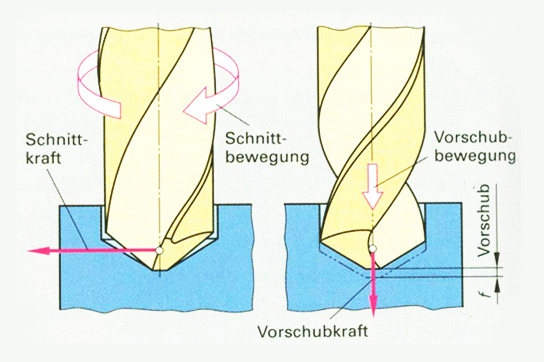

Cutting motion can be divided into main movement and feed movement. The main movement is the most basic motion that makes the workpiece and the cutter produce relative motion for cutting. The main movement has the highest speed and the most power consumption. In the cutting motion, there is only one main movement. It can be done by the workpiece, or it can be done by a cutter, it can be a spinning motion, or it can be a straight line.

Category Archives: Technology

Technology page is shared the experience of technical talent in field of drill bit grinder, help you to resolve the technical difficulties, and makes you into a specialist of drill bit re-grinder.

Drilling problems and Solutions

| Question No. | Problem description |

| 1 | Aperture Ultra Difference |

| 2 | Horn Hole |

| 3 | Hole Roundness Is Not Good |

| 4 | Poor Surface Quality of Holes |

| 5 | Burr At The Exit of The Hole |

| 6 | Chipping |

| 7 | Back of Drill Bit Blocked Chips |

| 8 | Bit Breaking |

| 9 | Blocked Chips |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Solutions |

| ● | ● | ● | ● | ● | ● | Reduce tool nose run out | |||

| ● | ● | increase Inverted cone | |||||||

| ● | ● | ● | ● | ● | ● | ● | Reducing blade height difference | ||

| ● | ● | ● | ● | ● | Improving tool symmetry | ||||

| ● | ● | ● | Improving cutting edge type | ||||||

| ● | ● | Improving blade treatment | |||||||

| ● | ● | Increase point angle | |||||||

| ● | ● | ● | ● | ● | ● | Tool length reduction | |||

| ● | Select and use coating | ||||||||

| ● | ● | ● | Increasing internal cooling pressure | ||||||

| ● | ● | ● | ● | Cutting speed reduction | |||||

| Improving cutting speed | |||||||||

| ● | ● | ● | ● | ● | ● | Reduce feed | |||

| ● | Raise feed |

Your drill bit has a problem when is in use, you can use our drill bit grinder to repair, easy, simple, as long as a few minutes, your drill can be used. We are a professional drill bit grinder manufacturer, and welcome batch purchase of products.

Why choose drill bit sharpener to sharp the drills

A top quality collection of drill bits could make a pretty good – sized opening in your wallet, specifically if you acquire numerous of them. They need to last you for a long period of time ahead, however, if you take appropriate treatment of them. To do this, you need to save them in a tough situation. The situation must have different owners or areas to ensure that each little bit is kept independently. If you throw your drill little bits right into a tool kit or cabinet, as well as enable them to roll about freely, the suggestions and also the cutting edges could conveniently be damaged or dulled. One more point you should carry out in order to take correct treatment of your drill little bits is to maintain them honed so they could execute their finest. Pierce little bits could be honed over and also over once more. Naturally, the bigger the little bit, the even more times it could be developed. An included plus is: that by maintaining your little bits sharp in all times, you will really conserve deterioration on your electrical drill. The sharper the little bit, the smoother and also much faster it will certainly function.

Information On How to Use End Mill Grinding Fixture

Just due to the fact that an end mill becomes dull doesn’t mean you have to scrap it or buy a new one. You can easily regrind an end mill to be sharp again using a special fixture that enables you to grind the relief angle and the edge. By thoroughly following a strict procedure you can save many of dollars and save end mill from the scrap bin.

So how do we use the end mill grinder to repair the end mill?

How you can make cutter grinder do not tremble?

PURROS Cutter Grinder is the specialized machine for cutting the tools. Cutting is accurate and rapid, easy operation, with no skill requirement to grind. With Taiwan diamond grinding wheel, only one piece can complete all procedure. It can be equipped directly with an accurate angle and longer service life.

The best ways to improve the drill bit

Many drill problems develop from unreliable aiming. Right drill aiming will certainly to an excellent level remove drill damage and also in precise openings. Pierce directing ought to be diverse relying on the products to be pierced. General function drills, have a factor angle of 118o consisted of 12 ° to 15 ° clearance angle as well as with a carve side angle of from 125 ° to 135 °. Many drivers do not have actually the abilities needed completely hand aiming, Making use of basic drill directing equipments is very suggested. Drills are equipment directed at the manufacturing facility to a 118° angle to guarantee an appropriate as well as consistent factor angle, equivalent cutting lips as well as right sculpt side angle.

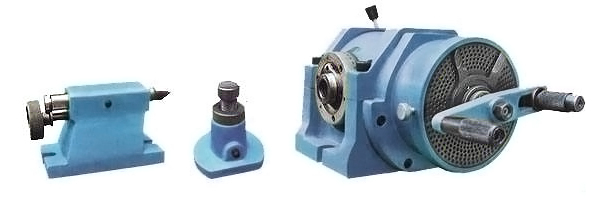

Making Use Of a Dividing Head

As well as Making One for Your Lathe A dividing head is a device that is utilized to split a circle right into equivalent departments. I am not describing levels or radians, so do not believe in those systems. Believe departments. Have you ever before aimed to set out a circle separated right into say, 37 equivalent components? It’s a breeze with a dividing head. Imagined listed below is an instance of a normal device.

Deep hole Gun Drilling Machine

If you require aid in preparation or addressing technological issues, our team gets on hand to supply assistance. All our solutions are given with one objective in mind: To provide the finest weapon drills grinding accessory as well as the most effective solution at one of the most practical price.

Treatment of drilling machines

Lubrication:

Lubrication of the drilling machine is essential due to the fact that of the warmth and also rubbing created by the relocating components. Tidy each equipment after usage. Run all devices with treatment to prevent exhausting the electrical motor.Continue reading

The failure mode of the drill bit [2]

There are several failure mode of the drill bit. PURROS summarizes the following situations:

Edge wear

Cause

1. Rigid and not tight enough

2. Beating too big

3. Inverted cone is too small

4. The coolant oil is not enough