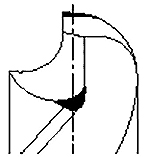

In the process of metal cutting, twist drill cuts the metal layer on the workpiece, at the same time, the workpiece and chips acts on the twist drill, causing the twist drill wear off. Normal wear off is inevitable, but abnormal wear is not acceptable. Such as abnormal wear on corner part of twist drill, Now, PURROS Machinery will enumerate these questions, and how to solve them.

- Cause: Twist Drill Bit Late Regrinding.

Solution: Regrind after a shorter time of use; do not wait until twist drill bit is blunt. - Cause: Bad Alignment (for Lathe Turning)

Solution: Check and adjust the alignment on the lathe. - Cause: Cutting Speed of Machining Too High.

Solution: Decrease the cutting speed during cutting machining. - Cause: Point Dimensions are Not Suitable (Point Angle Incorrect)

Solution: Select correct point dimensions, here you can use the twist drill bit grinder to regrind point angle. - Cause: Twist drill materials are not suitable.

Solution: It means maybe the rigidity of twist drill is not enough, choose suitable tool materials. - Cause: Coolant is Not Suitable

Solution: Change coolant for cooling