Mold manufacturing is a process of removing materials, which makes cutting tools (such as drills and end mills) the pillars of any mold manufacturing operation. They make the constantly used cutting tools dull quickly. Since end mill grinders are important in the manufacturing of molds, here are some tips to help keep end mills sharp for production.

Tip one: Buying a new one- In a mold manufacturing process, you can discard an end mill once it is no longer sharp, and replace it with a new tool. However, this can be an expensive method when used for a long-term as cutting tools can be pricey. For cost analysis purposes, if 30 end mills at $20.00 each are required to be purchased every month, that’s $600 each month. This wouldn’t be the most cost-effective technique to keep your end mills sharp, especially if the volume is high. However, this can be justifiable if the volume is low.

Tip two: sending your tools to an end mill sharpening service. There are various companies offering third-party services around you. In examining cost, if the average price to sharpen a two flute end mill is $5 and you need to sharpen 30 dull end mills every month, that’s $150 per month to be spent to sharpen your cutting tools. Also, these calculations do not acknowledge other factors affecting your budget such as transportation charges, and the need for extra machine and inventory downtime. Most shops that specialize in third-party sharpening services often have low volumes or trade other resources.

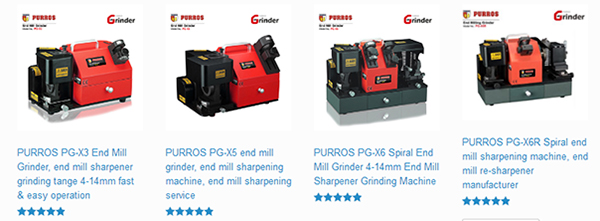

Tip three: purchasing an end mill grinding machine to hone your end mill on the spot. There are various end mill grinders in the market ranging from user-friendly equipment to complex machines. Purchasing an end mill grinding attachment is an investment that is initially expensive, but these sharpeners can quickly be paying. The benefits of getting your own end mill sharpening machine include customizable sharpening, limited machine downtime, no extra inventory needed, and no transit times.

Buy end mill grinder, drill bit re-sharpening machine now>>

There are different sharpening needs for different applications and there is no exception to mold making. Whether you are buying a new drill bit grinder or sending to a third party sharpening service, the need for sharp cutting tools is predominant in mold making. It is essential for you to consider the effects of caring for your cutting tools and the most cost-effective method for their operations,